Custom-Bilt Metals Mobile Manufacturing Equipment

Last week, Romtec’s production crew worked with Custom-Bilt Metals, a roofing manufacturer, to produce several 50’ sections of blue metal roofing at our production yard. Typically, we purchase building materials from manufacturers or vendors and get materials delivered to our yard or drop-shipped to the construction site. From our yard, the materials get staged, palletized, and shipped to the job site as a complete building package. This is the best process for most projects. Since this project required such large roofing sections, Custom-Bilt Metals offered to send its mobile manufacturing equipment to our yard to reduce the freight costs of shipping these large panels.

Cutting Shipment Costs and Learning a New Manufacturing Process

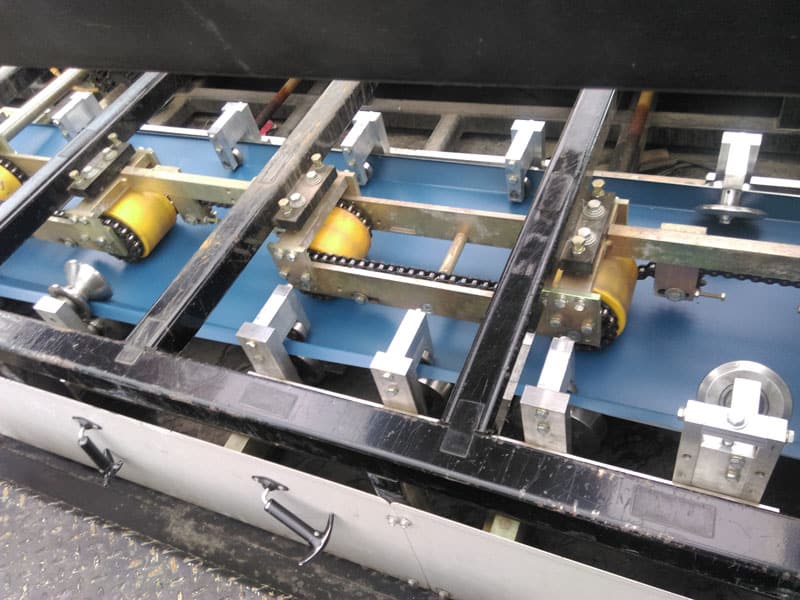

Custom-Bilt Metals has been a great roofing vendor for Romtec over the years. When facing this requirement, they offered a unique solution that ultimately benefitted our end customer. Sending one of their technicians with a mobile roll forming machine directly to Romtec and manufacturing the roofing in our yard is a big help, and it gave us a chance to see a different technology than we commonly work with. The machine is fed with coiled steel and with a series of gradual bends produces standing seam metal roofing. This cut shipping costs in half for the roofing. Now it will only need to be shipped from Romtec to the job site. Although the price reduction was the primary reason for this method, it was not the only benefit this process offered Romtec.

Quality Checking Each Panel

Producing the metal roofing onsite also allowed our production crew to “quality check” each panel as it was being roll formed. This process was basically a formality in this instance. Shipping metal roofing through third party freights lines can sometimes result in damages. Unlike many roofing vendors, Custom-Bilt Metals palletizes its roofing shipments to protect the freight. In either scenario, it is important to quality check roofing shipments to make sure it wasn’t damaged when using a third party freight vendor. Additionally, many of Romtec’s buildings are designed to match other buildings. Any changes during production runs for color can be very noticeable in these applications. Using the same coil of steel to produce all of the roofing eliminates any chance of this occurring. Working with a great partner like Custom-Bilt Metals helps Romtec design, supply, and construct buildings and structures for our clients. Contact Romtec today and get started on your unique building design!